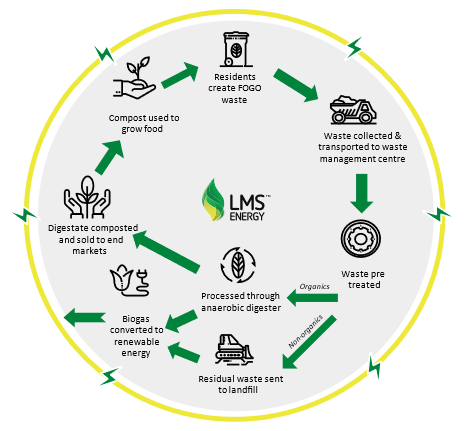

From green bin to green power: internationally proven technology to recover energy and nutrients from organic waste.

What will the facility look like?

What’s it all about?

LMS Energy (LMS) is working with Wyndham City Council to develop an organic resource recovery facility within Council’s existing Refuse Disposal Facility (RDF).

The organic processing facility will recover Wyndham residents’ food and garden organic waste as renewable energy and a nutrient-rich digestate compost product using anaerobic digestion technology.

Importantly, this organic waste is already received at the Wyndham RDF, so the LMS facility is not generating (or attracting) any additional organic waste. It is simply diverting it to an on-site processing facility to produce both renewable energy and compost.

The renewable energy would be generated through the existing renewable energy facility that has been operating on-site for more than a decade, and the compost would be handled by local composters or directly by farmers.

How does anaerobic digestion work?

Organic material naturally breaks down over time, for example on forest floors, in wetlands and in landfills, decomposing to release nutrient-rich material and biogas. The biogas is primarily methane and ‘biogenic’ carbon dioxide.

Anaerobic digestion (AD) technologies use these natural processes in a controlled environment to maximise food and garden organic waste recycling. AD facilities use sealed containers without any oxygen to enable accelerated decomposition of organic wastes. The containers are purpose designed to provide optimal conditions for the complex microbial communities that naturally break down (digest) the organics and contain and capture the biogas produced.

The biogas produced would be used to generate renewable electricity.

This facility would also produce a solid, nutrient-rich digestate for composting and use on soils.

.png)

Why AD?

Internationally, AD has emerged as a preferred way to recover food and garden waste, offering advantages by producing renewable energy as well as superior emissions reductions and avoidance of odour issues. Around 132,000 digesters and 50 million on-farm micro-digesters operate globally.

A significant benefit is that AD is enclosed, meaning odour and other emissions are minimised.

AD allows both the energy and nutrients in our food and garden wastes to be captured in addition to compost to help local farmers improve soil health.

Based on more than five years of detailed research, LMS has developed an Australian-first dry AD technology, designed to process organic waste under Australian conditions. It has a patent pending.

Where will the facility be developed?

LMS proposes to build and operate the Wyndham Organics Processing Facility on a small portion of around 14,000 m2 at the Wyndham RDF at 420 Wests Road, Werribee. The Wyndham RDF is located approximately 40 km southwest of Melbourne’s CBD and 10 km southwest of Werribee, within the municipality of the City of Wyndham. It is recognised in Sustainability Victoria’s Statewide Waste and Resource Recovery Infrastructure Plan (2018) as a Hub of State Importance.

What is happening now?

Design, Planning & EPA application preparation

LMS is currently working on detailed engineering and design for the project, which includes specialist studies to identify and address any air, noise and fire risks. We are developing our planning and EPA applications and expect to lodge both applications in Q3-Q4 2024.

The key details of the project are summarised below.

The project will process up to 10,000 tonnes per annum of Wyndham’s food and garden organic waste (green-lid bin) in its first year. Importantly, this organic waste already is entering the Wyndham RDF, so the LMS facility is not producing any additional organic waste, simply processing a portion of the local community’s organic waste at an on-site facility.

Due to the modular nature of the organics processing facility, there is opportunity to scale up the facility in the future. Any significant scaling up would require further approvals from Council, community consultation and EPA assessment.

Biogas produced at the AD facility will be used to produce around 1,000 MWh of electricity in the project’s first year – equivalent to powering 230 Victorian homes. This is expected to be scaled up in future years.

The project will abate more than 7,000 tonnes of carbon dioxide equivalent emissions (CO2e) annually – equivalent to removing 3,000 Australian cars from the road.

The project will create up to 37 jobs during construction, and around five full-time jobs once operational. More ongoing jobs would arise in any scaling up. In addition, LMS is committed to using local services for project delivery and complementary services where possible.

The total economic investment to deliver the project is more than $5 million.

This is in addition to the LMS’ Derrimut Manufacturing Hub, Control Centre, and Administration Office that LMS has purchased and developed in the Council area, injecting further economic investment into the region.

The project has been awarded $550,000 funding under Sustainability Victoria’s Bioenergy Fund.

Wyndham City Council has signed a Material Supply Agreement which would see 8,000 - 10,000 tonnes of existing organic waste diverted to the facility.

Fresh Select has provided a letter of support for the project.

Frequently Asked Questions

The organic waste would be received from the Wyndham community, via existing household green bins. Wyndham’s food and garden waste is already transported to the Wyndham RDF for sorting at the on-site transfer station. Some of this material will simply be diverted to the new Wyndham Organics Processing Facility once operational.

In anaerobic digestion (AD), organic waste (including food and garden waste) is broken down by a natural process.

Naturally occurring bacteria break down the organic material through several phases to produce biogas and a nutrient-rich digestate.

AD facilities use sealed containers without any oxygen to enable accelerated decomposition of the organic material. The containers are purpose designed to provide optimal conditions for the complex microbial communities that digest the matter and contain and capture the biogas produced.

This biogas is then utilised in purpose-built engines to be converted to renewable electricity.

The digestate is for composting, circulating nutrients back to our soils.

The biogas will be piped to LMS’ existing bioenergy facility which has operated at the site for over a decade. The facility uses gas-fuelled engines to convert biogas to renewable energy. This electricity is exported to the local electricity network to power local homes and business, or may also be used to power on-site infrastructure – to reduce the need to use electricity from the grid.

AD produces a nutrient-rich product called digestate, which can be used to improve soil and agricultural production.

LMS’ ultra-dry AD technology produces a solid digestate which is very similar to compost. It will be further processed and matured in a composting operation to EPA requirements.

Digestate can be used to enrich and improve soils, returning valuable nutrients to our soils to be cycled back into growing more food.

Digestates can help displace mineral fertilisers, reducing fossil fuel use, and have been shown to also benefit soil condition, soil carbon and water usage.

No. One of the key advantages of anaerobic digestion is it is an entirely enclosed process for the recovery of organics, effectively reducing the potential for odours and environmental emissions relative to other recovery processes. Furthermore, it captures and harnesses the methane gas arising, converting it into useable, renewable energy rather than it being released into the atmosphere.

The project is not expected to have any environmental impacts. To ensure this, specialist reports will be prepared as part of our planning and design process to identify and detail any potential impacts to land, air or waterways and how they would be managed. LMS is committed to ensuring the project delivers an overall net environmental benefit for Wyndham and the community.

There are no negative health implications created by the project. LMS is preparing comprehensive planning and EPA applications which include specialist studies for air, noise and odour. The facility is being designed to minimise any impacts and provide an overall benefit to the community.

There will be no additional trucks, as Wyndham’s food and garden waste is already transported to the Wyndham RDF for sorting at the on-site transfer station. Some of this material will simply be diverted to the new Organics Processing Facility once operational.

There may be some short-term increases in truck movements during the construction phase. Construction activities, including an increase in heavy vehicle movements on the local road network, have the potential to impact traffic. However, these impacts are anticipated to be relatively minor due to the scale of the project and the neighbouring industrial land uses.

Absolutely. We're committed to providing job opportunities for people in our local community for both skilled professionals and those seeking entry-level positions. This will contribute to the local economy and also foster community involvement and growth.

In addition, LMS has established a Derrimut Manufacturing Hub, Control Centre, and Administration Office in the Council area, injecting further economic investment into the region.

Unlike waste incineration, which involves burning waste to generate heat and energy, our process relies on anaerobic digestion. Anaerobic digestion provides a controlled setting for the natural breakdown of organic materials without oxygen – comparable to our own bodies’ digestion processes or what you can see occurring in wetlands. These breakdown processes produce methane gas and energy without emitting harmful pollutants. The methane gas captured will be used to create renewable electricity at LMS’ existing bioenergy facility for export to the local electricity network.

Renewable electricity would be generated from the AD facility’s biogas at LMS’ existing bioenergy facility. This renewable electricity is exported to the local electricity grid.

The facility is being developed by LMS Energy, in partnership with Wyndham City Council. LMS will develop, operate, and invest in the facility, while Council will supply the food and garden organic waste, collected from Wyndham residents.

LMS Energy

LMS is Australia’s most successful biogas company and largest emissions reducer under the Emissions Reduction Fund. It has 66 biogas projects across Australia, New Zealand and the United States, partnering with more than 40 local councils. LMS is a multi-generational, family-owned business that is 100% Australian owned and operated, employing nearly 300 people. LMS Energy projects abate methane emissions and generate enough renewable energy to power around 110,000 Australian homes each day.

Register your interest

Register your details here to receive project specific updates regarding the proposed Wyndham Organics Processing Facility